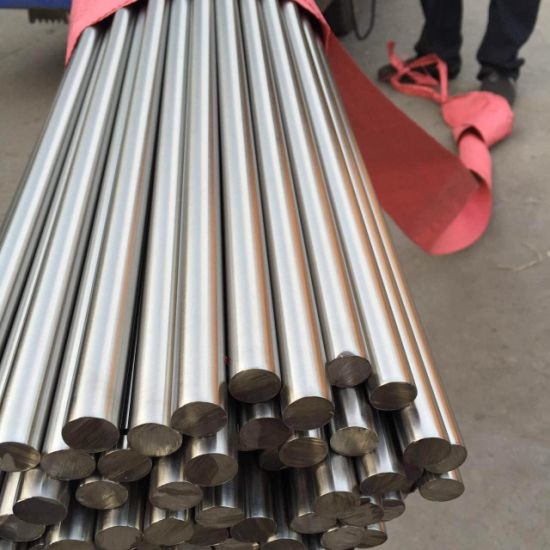

303 stainless steel round bar is a type of austenitic stainless steel that contains 17-19% chromium and 8-10% nickel. It also contains sulfur and is sometimes referred to as "sulfur-bearing" stainless steel.

Chemical Compositions (in %):

| C Max | Mn Max | P Max | S Max | Si Max | Cr | Ni | Mo | Other Element |

| 0.15 | 2.00 | 0.045 | 0.015 Min | 1 | 17.0/19.0 | 8.0/10.0 | --- | E-4-1 Max |

303 stainless steel round bar is commonly used in applications that require good machinability and corrosion resistance, such as bolts, nuts, and screws. It is also used in the manufacturing of gears, shafts, and other components that require high strength and good resistance to wear and tear.

The sulfur content in 303 stainless steel round bar improves its machinability, making it easy to machine and produce complex parts with tight tolerances. However, it can also lead to brittleness and reduce its ductility, which can limit its use in certain applications. The chromium and nickel content provide good corrosion resistance and improve the material's ability to withstand high temperatures and harsh environments.

303 stainless steel round bar can be hardened by cold working or heat treatment, such as annealing, to improve its mechanical properties. It can also be welded and polished, although care must be taken to avoid overheating and excessive strain hardening.

Overall, 303 stainless steel round bar is a versatile material that offers good machinability, strength, and corrosion resistance, making it suitable for a wide range of industrial and commercial applications where these properties are important.